Bridge 35

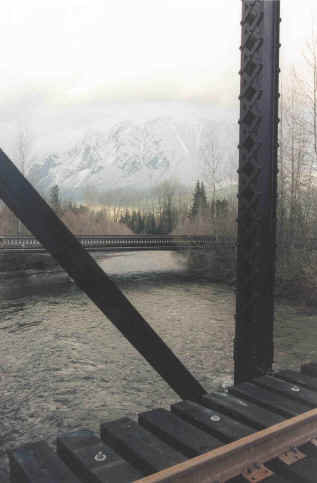

Bridge 35 Lassig Bridge and Iron Works, 1891-built through-pin-connected Pratt truss. Restored in 2003; purchased 1981 from the Burlington Northern Railroad. This 160-foot long through-pin-connected Pratt truss was constructed in 1891 by Chicago’s Lassig Bridge and Iron Works. However, it was not built in North Bend— it was the seventh crossing of the Yellowstone River on the mainline of the Northern Pacific Railway in Montana. 1891’s heaviest imaginable locomotive was just a few hundred thousand pounds. Just over thirty years later, the largest mainline locomotives were nearly 1.2 million pounds. So, when a new, stronger bridge was erected over the Yellowstone in 1923 to support these new super-sized locomotives, the old bridge was dismantled, moved to North Bend, and re-erected over the South Fork of the Snoqualmie River on a lighter density line called the Snoqualmie Branch. The structure includes the steel span and 798 feet of ballast deck timber trestle approaches. The timber trestle portion was built in 1929.

Bridge 35 Lassig Bridge and Iron Works, 1891-built through-pin-connected Pratt truss. Restored in 2003; purchased 1981 from the Burlington Northern Railroad. This 160-foot long through-pin-connected Pratt truss was constructed in 1891 by Chicago’s Lassig Bridge and Iron Works. However, it was not built in North Bend— it was the seventh crossing of the Yellowstone River on the mainline of the Northern Pacific Railway in Montana. 1891’s heaviest imaginable locomotive was just a few hundred thousand pounds. Just over thirty years later, the largest mainline locomotives were nearly 1.2 million pounds. So, when a new, stronger bridge was erected over the Yellowstone in 1923 to support these new super-sized locomotives, the old bridge was dismantled, moved to North Bend, and re-erected over the South Fork of the Snoqualmie River on a lighter density line called the Snoqualmie Branch. The structure includes the steel span and 798 feet of ballast deck timber trestle approaches. The timber trestle portion was built in 1929.

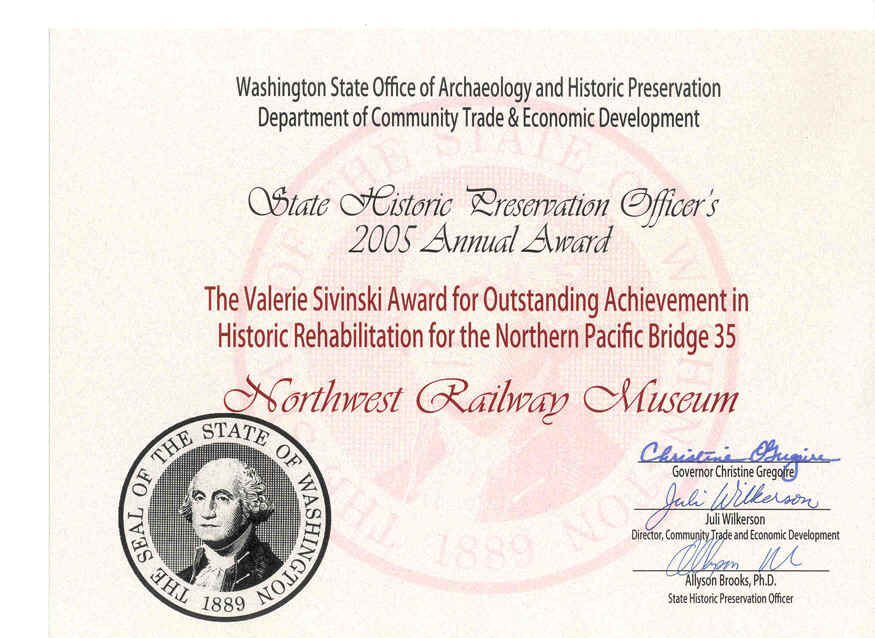

Bridge 35 received a major rehabilitation in 2003/2004. The Bridge 35 Rehabilitation received the 2005 Washington State Historic Preservation Officer’s Valerie Sivinski Award for Outstanding Achievement in Historic Rehabilitation.

Bridge 35 received a major rehabilitation in 2003/2004. The Bridge 35 Rehabilitation received the 2005 Washington State Historic Preservation Officer’s Valerie Sivinski Award for Outstanding Achievement in Historic Rehabilitation.

Bridge 35 was constructed in 1891 in Montana as the fifth crossing of the Yellowstone River, on the mainline of the Northern Pacific Railway. This 160-foot through-pin-connected Pratt truss was built to what we would now consider a Coopers E33 rating. It could support double headed locomotives of any size in operation in 1891.

By the 1920s, the increasing size of Northern Pacific’s locomotives required bridges able to support greater weight. So in 1923 a new bridge was erected over the Yellowstone River. The old bridge was dismantled, moved to North Bend, Washington, and rebuilt over the south fork of the Snoqualmie River. Bridge 35 in North Bend also incorporates 798 feet of ballasted deck timber trestle constructed in 1929.

By the 1920s, the increasing size of Northern Pacific’s locomotives required bridges able to support greater weight. So in 1923 a new bridge was erected over the Yellowstone River. The old bridge was dismantled, moved to North Bend, Washington, and rebuilt over the south fork of the Snoqualmie River. Bridge 35 in North Bend also incorporates 798 feet of ballasted deck timber trestle constructed in 1929.

All bridges on the Museum’s Snoqualmie Valley Railroad were built by the Northern Pacific Railway. They are inspected annually for safety and any evidence of deterioration.

All bridges on the Museum’s Snoqualmie Valley Railroad were built by the Northern Pacific Railway. They are inspected annually for safety and any evidence of deterioration.

Periodically, a detailed study of structural timber is completed that includes ultrasound testing to detect damaged timber, and core samples using a half inch drill. A “map” of wet or rotten wood is made to track continued deterioration. When a suitable factor of safety cannot be maintained, the timber is replaced.

By the spring of 1999, the Museum began the lengthy process of searching for funding and securing permit approvals. Funding was awarded by the King County Cultural Development Fund, and by the Washington State Department of Transportation from the Federal TEA-21 program upon recommendation of the Puget Sound Regional Council. The $492,000 project began construction in September 2003.

Bridge 35 was last repainted in 1964. This traditional coating system began to fail in the late 1990s when peeling paint and some corrosion began to appear on the lattice work. The primer and top coat contained approximately 17% lead, so any plan to repaint needed to incorporate a lead abatement plan. The Museum opted for encapsulation and selected a painted system to achieve this.

The Museum selected Wasser moisture cure urethane bridge coatings. This system consists of a zinc primer, micaceous iron oxide intermediate coat and a urethane top coat. These coatings can be applied with a relative humidity up to 99% over a wide range of temperatures.

Most of Bridge 35’s surfaces were in good shape, and the new coatings effectively encapsulate existing well-adhering lead coatings. So the Museum decided to specify abrasive blasting only where corrosion was present.

The entire steel structure was treated with bleach to kill moss and then cleaned with pressure washers. To assure environmental protection, a system of tarps was erected to catch wash water and any grit from sand blast operations.

The entire steel structure was treated with bleach to kill moss and then cleaned with pressure washers. To assure environmental protection, a system of tarps was erected to catch wash water and any grit from sand blast operations.

Once the timber deck was removed and the structure cleaned, abrasive blasting began. The grit selected was Cleanblast with Blastox. Blastox is an agent designed to neutralize lead, rendering the waste mixture of grit and paint non-hazardous. Heavy blasting to white metal was performed where corrosion was found. Other areas were blasted only to remove loose or poorly-adhering coatings.

The entire cleaning and painting operation took just 10 working days, but work was distributed over a five week period because of poor weather.

The new coatings include 3 – 5 mils of MC Zinc primer, 3 – 5 mils of Ferrox B intermediate coating, and 3 – 5 mils of MC Luster semi-gloss top coat. This painting procedure gives the bridge an appearance very similar to what it had shortly after its 1964 paint application.

Prior to deck replacement, five pile caps were replaced. This required jacking the entire bridge using 8 hydraulic jacks, cutting the old caps into short sections using a chain saw and then inserting a new 30-foot long beam from the side. Note the steel I beam sections in between the piles. During jacking, these beams spread the bridge’s weight over a larger surface to reduce the likelihood of jacking failure. The silt found between the piles in incapable of supporting more than 2,000 pounds per square foot.

After insertion work was completed, the caps were strapped to the piles to restrict movement during a seismic event. Work was completed in just two weeks.

Replacing a timber deck on a railway bridge can be hazardous. Workers are restrained with safety harnesses slowing their progress. Rails are laid across the bridge as the timber deck is placed and additional materials are delivered by rail-mounted crane.

The new deck consists of 141 10 inch square by 12 feet Douglas Fir ties treated with ACZA (ammoniacal copper zinc arsenate) and stained black. Creosote products were banned on this project by the Washington State Department of Fish and Wildlife.

The rail is 112 lbs/yard, slightly heavier than the “original” 90 lb/yard rail. The heavier rail was applied to help spread load better through great beam strength in the rail section, and by the use of larger, double shoulder tie plates.

Many railroads used bridges and other structures as convenient advertising mediums. Bridge 35 is just 150 feet from highway 10, the precursor to Interstate 90 and today known as North Bend Way. In 1981, I-90 was aligned and moved about 1 mile to the south. Part of the multi-year I-90 project led to the abandonment of the much of the Snoqualmie Branch.

Bridge 35’s original “Ship Northern Pacific Travel” advertising sign was damaged by vandals and 50 years of weathering so rehabilitation was not practicable. A new sign was faithfully copied from the original and reinstalled. Only a few minor “improvements” were made: urethane paint instead of alkyd, oak mounting brackets instead of creosote-treated fir, and galvanized bolts instead of plain steel.

McConnell Construction’s Tom McConnell bravely climbed to the top of the bridge to install the new sign. He was assisted by Walt Weaver, the Museum’s Civil Engineer and project inspector.